Solving apple waste at the start

About the project:

This project is a research focused project that took two and a half months.

Date: Spring 2021

The Team:

This project was done by a team of three industrial design students all third years including myself. My role on the team was to conduct apple and food waste research, ideation, chemistry research, visual exploration, and contacting experts.

The Advisers:

We received knowledge and feedback about food waste from Chris Hartman from Headwater Foods. I contacted Chad Kirby from Kirby's Farm, who let us tour the farm and taught us about apple production.

The Design Goal

RIT students will work in teams to address the BioDesign challenge's goal of Sustainable Consumption and Production with a focus on food waste. Partnering with Headwater Foods of Rochester, teams will consider food waste for apples or milk and conduct research that allows for hands-on-experimentation.

The Challenge

Problem: Apple consumption and production in its current state is wasteful and lacks a high level of sustainability.

Opportunity: Apple farming and harvesting has potential for improvement to become more efficient so less apples are wasted.

Big Question: How can we make apple production less wasteful, more sustainable, and better for farmers and apple workers?

Biodesign Challenge

The Biodesign challenge is an international team competition with an emphasis on design engaging in science. They partner university students with scientists, artists, and designers to envision, create, and critique transformational applications in biotech.

Research

Apple Waste

Appearance is one of the most important factors to consumers when buying produce. The percentage of consumers selecting apples with defects was equal or lower than 15%. Most bruising occurs when the apples are dropped into transportation crates. If dropped from a height of 1 foot into a crate, 75% of apples bruise.

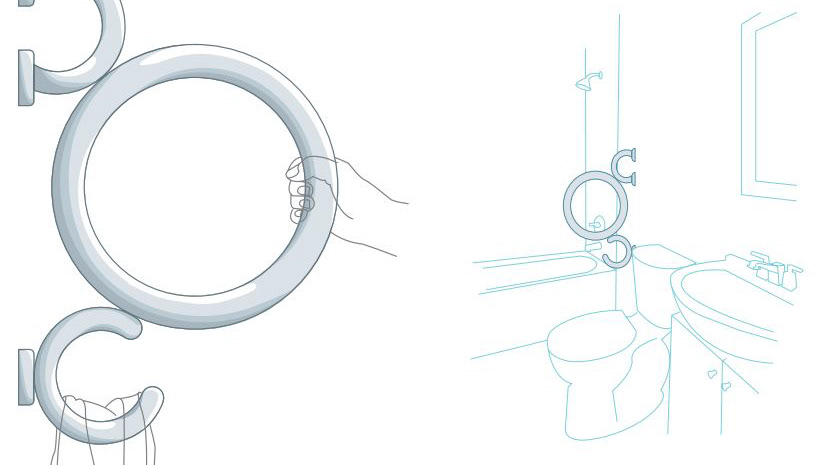

Lowering drop height or placing a cushion inside apple crates was found to drastically reduce bruising.

Apple Farming

Apples are grown in orchards and handpicked off apple trees. Apple farming often involves growing a variety of apple types. Innovation in the industry is rather slow, as many practices have not changed for decades.

In the apple farming industry, apples are either fresh apples or processing apples. Fresh apples are the ones that produce a profit and go to grocery stores or schools. Processing apples are juiced or made into sauce and in most cases give apple farmers no profit.

As little as 1 in 12 apples harvested produce profit for apple farmers.

Chemistry of Apple Bruising

Apple cells have big organelles (sacs) known as vacuoles and small organelles known as chloroplasts and mitochondria. Within the vacuoles is a substance known as polyphenol and within the chloroplasts and mitochondria is a substance known as polyphenol oxidase.

When the cells are damaged by outside forces (falling into crates), the vacuoles, chloroplasts, and mitochondria all break and the contents mix together. The polyphenol and polyphenol oxidase come in contact and produce catechol melanin. Catechol melanin is what causes the unappealing brown part of the bruises.

If we can reduce the impact of apples, then the cells would not break, the two chemicals would not come in contact, and the catechol melanin would not form.

While the reaction that forms catechol melanin is reversible, it is more easily avoidable.

Reframed Problem

How can we reduce the damage caused to tree fruits during the transportation phase by redesigning the packaging while still making the process easy and cost effective in order to reduce food waste?

Goals

Cost Effective

Reduce food waste at the source

Implementable today into current systems

Easily expandable and updateable in the future

Expandable to other produce

Ideation and Testing

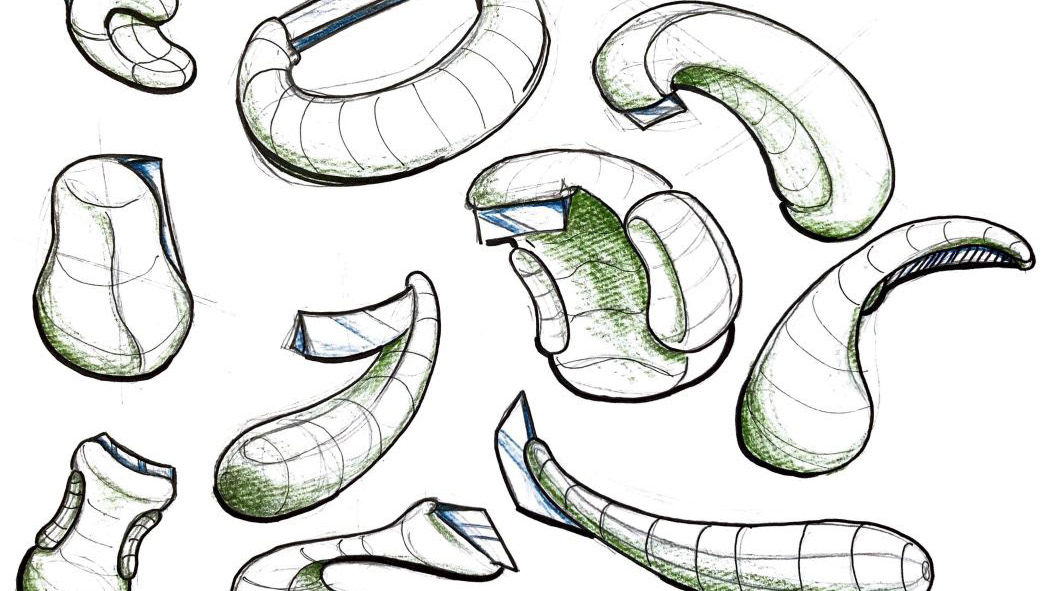

Divergent Ideation

Convergent Ideation

Testing

Apple Dropping

We dropped two apples from 1 foot, 2 feet, and 3 feet on to wood and on to foam separately. Each apple was labeled what height they were dropped from and what material they were dropped onto. The number indicated the height while apples A and B were dropped on wood and C and D were dropped on foam.

Apple Documentation

We recorded the point of impact on the apple by taking pictures of each apple. Pictures were taken immediately following the drop then stored at room temperature in a dark space. In order to see the effects over time photos were then taken 24, 48, and 72 hours after.

The results concluded that dropping onto foam had significantly less bruising than onto wood.

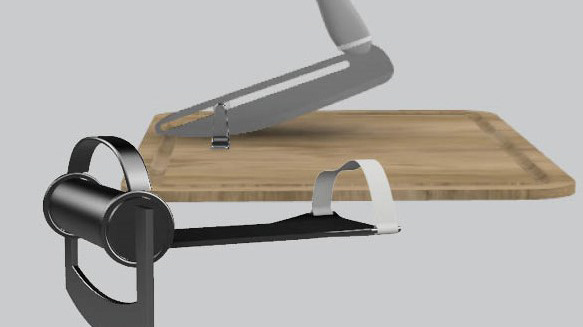

Final Design

Longevity

Our product is meant to be used multiple times for multiple years after being implemented, similarly to the crates used by apple farmers currently.

Implementable

In order to appeal to farmers who are not in a position to completely change their apple processing system, our design can be easily added to existing systems.

Affordable

The profits gained from prevented apple bruising are more than enough to counter the cost of our product per crate.

Sustainable

As part of the over all goal to reduce food waste, our product is made from a sustainable material so that excess waste is not generated.

Feedback

In judging against other students for the BioDesign contest, we received

honorable mention as “Most Implementable”

honorable mention as “Most Implementable”

Summary

What: A ready to implement product that prevents against bruising of apples and is appealing to apple farmers

How: A foam apple crate insert for during transportation from orchard to processing facility

Why: To prevent food waste within the apple industry and other hand harvested produce